Metal Stamping Lubrication System

Metal stamping requires lubrication to minimize friction dissipate heat reduce tool wear and maintenance and prevent galling. See how the AutoJet Lubrication System applies applies lubricant uniformly and consistently to molds without waste and to sheet steel prior to pressing.

Sheet Metal Stamping Dies Processes Youtube

Press areas stay clean with Unist systems.

Metal stamping lubrication system. This leads to increased scrap premature tooling wear and as any metal stamper. In our previous post on the stamping system several environmental variables within production sheet metal stamping are mentioned. Without proper lubrication any metal forming process will quickly succumb to excessive wear leading to galling scoring and cracking of parts.

Low Volume Low Pressure. With metal forming lubricant solutions for material from 1 to over 72 wide we have the answers for metal formers struggling to apply fluid. Over 50 Years of Lubrication Solutions.

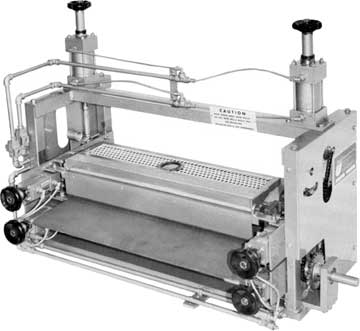

The Ultra is a turnkey solution for highly viscous lubricants up to 800 cps. The FlexSpray airless spray system that controls lubrication of metal stamping and drawing stock is now available in a five-gallon capacity unit for small-to medium-size production operations from the Pillsbury Chemical Oil Inc Detroit MI. Read reviews and stay informed with product new articles.

Back to all posts. Plan now to attend this important conference February 12-13 2020 in Novi Detroit MI focused on state-of-the-art technology processes and procedures for ensuring an optimal lubrication strategy for metal stamping and tool and die manufacturing. The role of lubrication in the stamping system.

The work material being stamped the proper tooling and the correct lubricant to help aid material flow inside the tool. Since 1964 Schaefer Tool Mfg. Metal Stamping Lubrication 101.

Reduce Safety and Environmental Concerns with a More Consistent Metal Stamping Process. TCR Incs consulting and integration services provide manufacturers with solutions for the challenges they face. Few things are more important in the metal stamping industry than an adequate in-die lubrication and coil stock lubrication system.

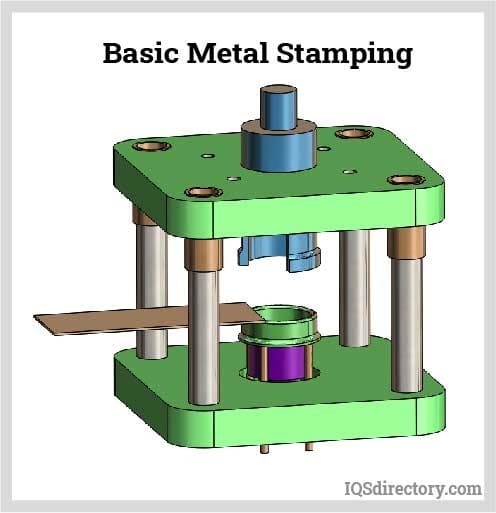

Die lubrication also reduces the potential for damaging the die due. Using Precision Spray Control our AutoJet Lubrication System eliminates the was. Every metal stamping process has at its core three key components that contribute to its overall success.

To compensate many stampers end up applying at least 50 more. Medium Heavy Duty Trucks and Buses Passenger Vehicle Motorcycle Lawn Garden Small Engine Electricity Generation Natural Gas Valves. Featured Resource AccuOil System.

Presented by MetalForming magazine and the Precision. Lubrication Technology for Metal Formers. Starting with the PreSpray I in 1964 we have been developing and improving lubricant application systems for metal stamping and other industries.

STAMPING Journal is the only industrial publication dedicated solely to serving the needs of the metal stamping market. Lubrication is arguably one of the most important aspects of the metal stamping process. Whether you are looking for manufacturers of metal stamping lubrication system ballscrew lubrication systems or micro lubrication systems of every type IQS is the premier source for you.

We provide engineered metal stamping systems upgrades to existing lines with aftersale service and repair for all makes of stamping equipment. Whether it is upgrades for production or safety on existing equipment or creation. Unfortunately standard lubrication systems like pads rollers and airless sprays do not usually apply a consistent coating of oil to the stock.

Milwaukee WI is a manufacturer of quality assemblies and metal stampings. Metal stamping processes require lubrication to minimize friction dissipate heat reduce tool wear and maintenance and prevent galling. Precise uniform application of oil on strip eliminates rejects and reduces operating costs.

AutoJet Precision Lubrication System for Metal Stamping. Since 1989 the publication has been dedicated to covering the cutting-edge technologies industry trends best practices and news that help stamping professionals run their businesses more efficiently. Reliable and effective the Alpha System offers an affordable turnkey lubrication application solution for small pressrooms or vanishing oil applications.

See how to reduce waste scrap and maintenance time in stamping operations. AutoJet Precision Lubrication System for Metal Stamping See how the AutoJet precision lubrication system applies lubricant to molds uniformly and. Die lubrication is designed to dissipate heat and reduce friction prolonging die life and decreasing down time from press room equipment failure.

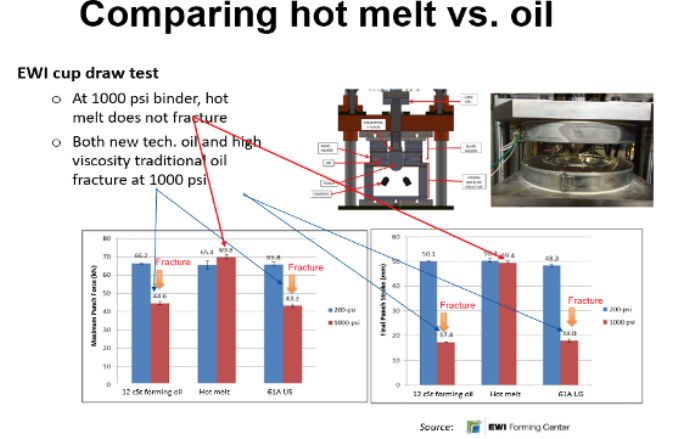

In that post we listed variables such as blank surface blank coating tool surface tool coating and blankdie lubrication. Slippery floors a messy press and stamped parts swimming in oil are just some of the headaches that Uni-Roller systems from Unist can eliminate. We serve many markets in the USA Mexico Europe and Asia.

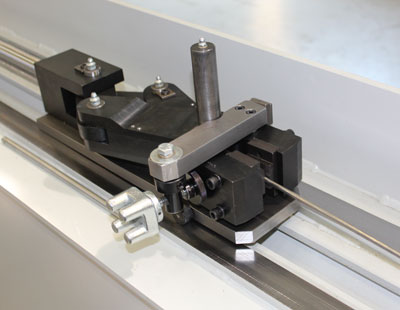

See how to improve metal stamping operations with Precision Spray Control. A well-thought-out and well-designed lubrication application system can provide access to some waste reduction. Lubrication system with a pair of piston-style nozzles Each lubrication system includes a pair of piston-style nozzles suitable for spraying light vanishing oil as well as heavy-duty oil.

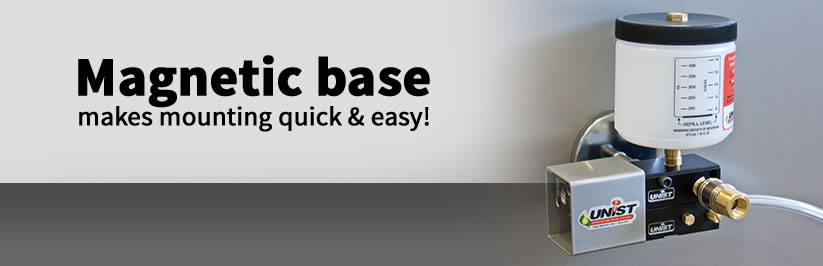

Here spray nozzles mounted to magnetic bases apply lubricant directly onto punches from the side of a die installed on a Bruderer 30-ton high-speed press. The lubricant is atomized with air at the nozzle to create an ultrafine spray.

Independent Manipulator Is Widely Used For The Automatic Handling Of Large Sheet Metal Parts Stamping In Multiple P Mechanical Power Electromagnet Manipulation

Airless Type Lubrication System Presspray I Lsp Industries Inc Oil Spray For Metal Stamping

Die Science Stamping Stainless Steel Part Ii

Skf Circoil Lube System Flo Components Value Added Partner And Distributor For Skf Brand Circulating Oil Lubrication Solutions Oil Conditioning System Fluid Circulation System Flo Components Automatic Lubrication Systems

Pax In Die Automatic Lubrication System Production Resources Inc

Diy Metal Stamping 10 Steps With Pictures Instructables

Roller Lubrication System Automatic Roller Lubricating System Mumbai India

Roller Lubricator With Roller Diameter 60 Mm

Fin Stamping Fluids And Lubricant

As A Professional Group By Accumulating Rich Experience Of Stamping Production Lines Kinglan Can Customize Complete Solution Manufacturing Stamp Robot Design

Lubricant Strategies For Stamping Aluminum Biw Parts And Closures Metalforming Magazine Article

Unist Product Cupping Press Coil Lubrication System

Machine Tool Lubrication System Pumps Fittings Bijur Delimon International

Stamping Press Repair And Other Related Press Room Equipment Imr Inc

Removing Scrap Efficiently During Stamping

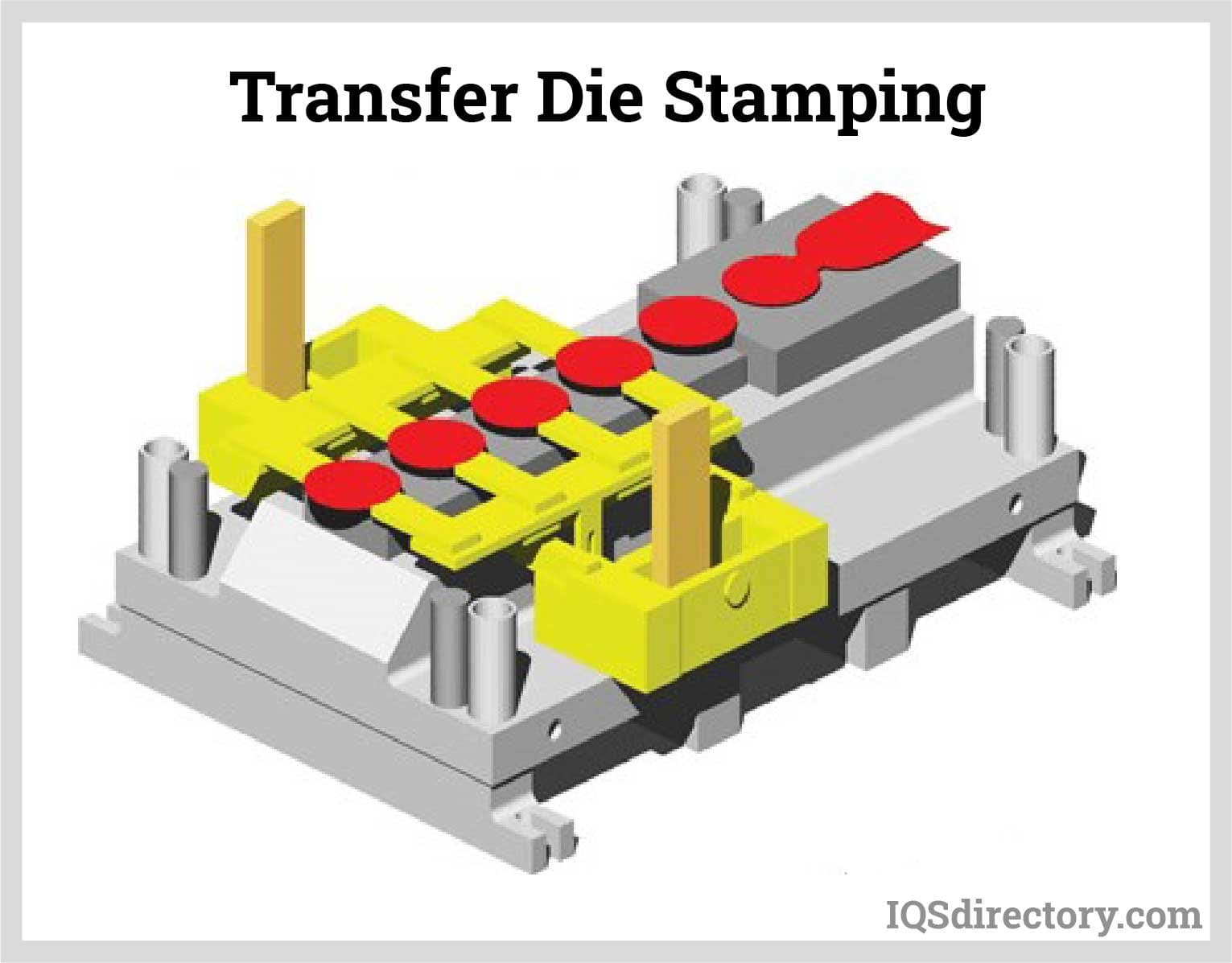

Die Stamping What Is It Process Steps Progressive Vs Transfer

Metal Stamping And Die Design The Definitive Guide Machinemfg

Metal Stamping And Die Design The Definitive Guide Machinemfg

Automated Coating Machines From Union Tool

Handling Metal Stamping Wastes Protecting The Environment And Your Business

Die Stamping What Is It Process Steps Progressive Vs Transfer

Oil Lubrication Unit Mini Roller Unist Inc Roller Continuous For Metal Stamping

The Ever Changing Automotive Stamping Industry In Canada

Metalworking Industry Conic Tooth Gear Wheel Machining By Hob Cutter Mill Tool Selective Focus On Teeth Sponsored Oil And Gas Metal Working Stamp Drawing

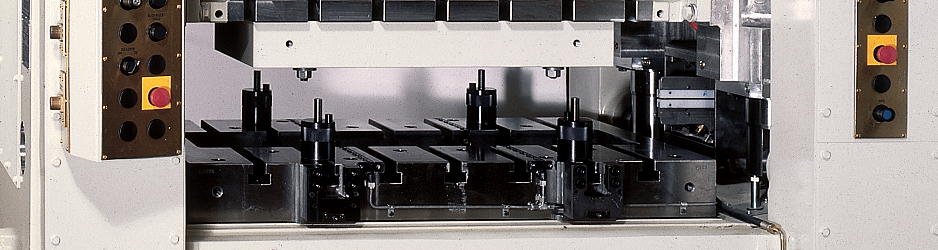

Stamping Specialty Metalworking Machinery Systems Inc

The Ever Changing Automotive Stamping Industry In Canada

China 280 Ton Metal Stamping Machine For Metal Blank Stamping And Punching China Power Press Press Machine

Punch Die Hydraulic Press Brake Affiliate Press Brake Press Brake Tooling Automobile

Cut To Length Lines Transfer Press Feed Lines Production Resources Inc

Roller Lubricator With Roller Diameter 60 Mm

Our Efficient Stamping Lubricant Stop Problems Such As A Messy Press Slippery Floors And Stamped Parts Soaking In Coola Lubricant Slippery Floor How To Apply

Diy Metal Stamping 10 Steps With Pictures Instructables

Mechanical Power Press Progressive Die Metal Stamping 250 Ton Punch Press Uncoiler And Feeder Youtube

Stainless Steel Stamping Metal Stamping Lubricants Case Study Irmco

Steel Belt Conveyors Heavy Duty Scrap Conveyor System Prab

Stamping Specialty Metalworking Machinery Systems Inc

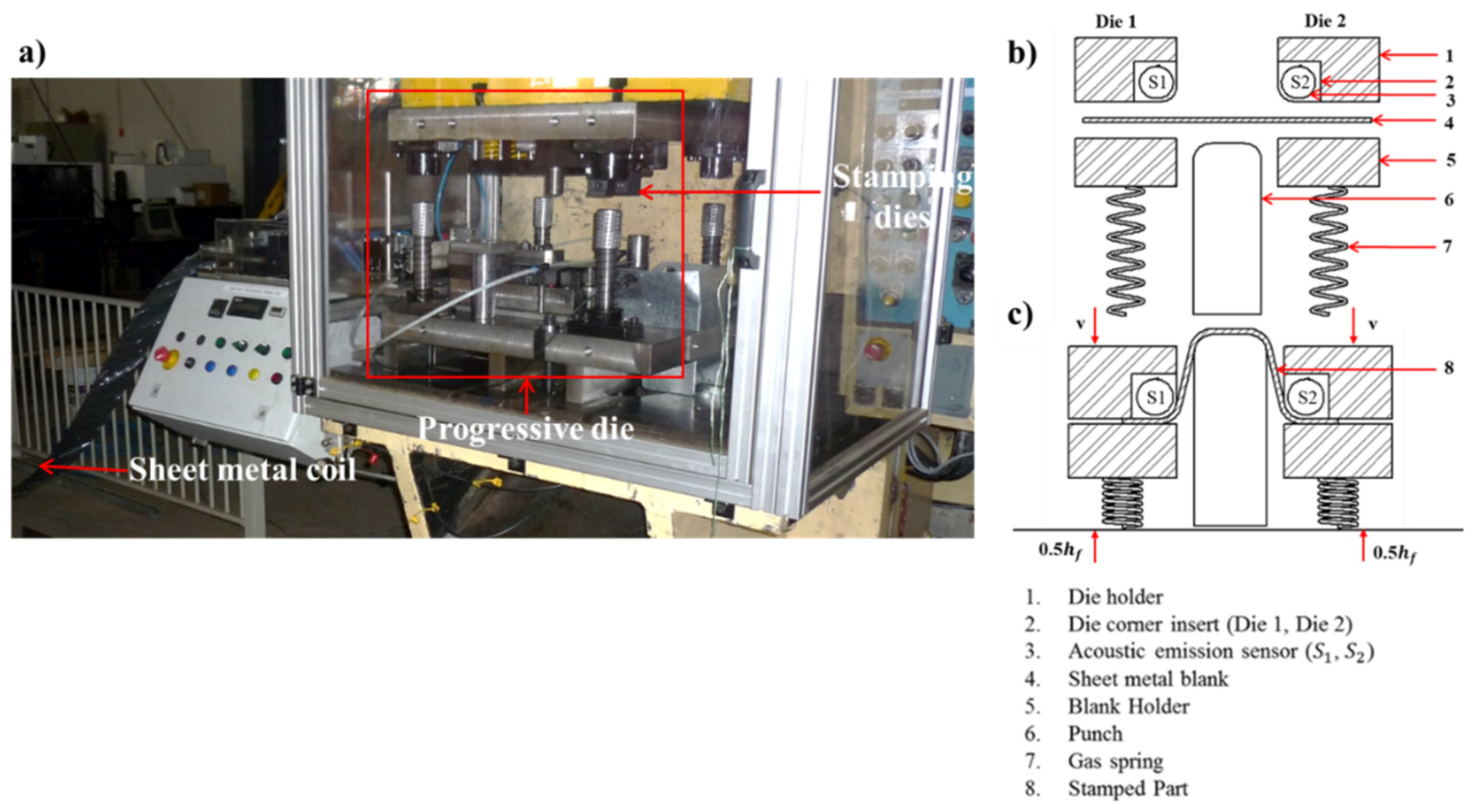

Lubricants Free Full Text Investigation Of Galling Wear Using Acoustic Emission Frequency Characteristics Html

![]()

Cut To Length Lines Transfer Press Feed Lines Production Resources Inc

China C1 280 Metal Stamping Machine For Metal Blank Stamping And Punching China Power Press Press Machine

Stamping Specialty Metalworking Machinery Systems Inc

Double Action Press Machine Press Machine Hydraulic Systems Pressing

Skf Circoil Lube System Flo Components Value Added Partner And Distributor For Skf Brand Circulating Oil Lubrication Solutions Oil Conditioning System Fluid Circulation System Flo Components Automatic Lubrication Systems

Our Capabilities Include The Production Of Progressive Dies Transfer Dies Single Stage Dies Multi Stage D Metal Extrusion Metal Stamping Dies Metal Stamping

Stamping Press Repair And Other Related Press Room Equipment Imr Inc

Aluminum Stamping Companies Aluminum Stamping Services

Spray Lubrication System Spray Lubricating System Manufacturer Mumbai India Manufacturing System Spray

Troubleshooting Stamping Performance

Typical Sheet Metal Stamping Operation 1 Download Scientific Diagram

Metal Stamping Equipment Concept Machine

Mms Uni Roller Stock Lubrication Systems

Roller Lubricator With Roller Diameter 60 Mm

Pin On Decoiler Straightener Feeder

Steel Belt Conveyors Heavy Duty Scrap Conveyor System Prab

Die Science Stamping Stainless Steel

Compound Die Mechanical Power Deep Drawing One Stroke

Skf Circoil Lube System Flo Components Value Added Partner And Distributor For Skf Brand Circulating Oil Lubrication Solutions Oil Conditioning System Fluid Circulation System Flo Components Automatic Lubrication Systems

Amazon Com Zonepack Digital Embossing Machine With Stamping Letter Hot Foil Stamping Machine Manual Tipper S Hot Foil Stamping Foil Stamping Embossing Machine

Pentacle Stamp Pentacle Stamp Metal Stamping

Roller Lubricator With Roller Diameter 60 Mm

Autojet Spray Lubrication Systems Spraying Systems Co

Audio Signal Analysis For Tool Wear Monitoring In Sheet Metal Stamping Sciencedirect

Pragestempel Messing Embossing Stamp Cnc Mill Cnc Milling Machine

Protecting Metal Stamping Dies

Unist Product Coolubricator Jr

1 Day Stamping Application Seminar

Stamping Research Gains Support

Otis Lubricants 1 Gallon Can Otis Elevator Company Etsy Otis Elevator Company Otis Elevator Lubricants

Roller Lubricator With Roller Diameter 32 Mm

Skf Circoil Lube System Flo Components Value Added Partner And Distributor For Skf Brand Circulating Oil Lubrication Solutions Oil Conditioning System Fluid Circulation System Flo Components Automatic Lubrication Systems

Roller Lubrication System Automatic Roller Lubricating System Mumbai India

Stamping Industrial Manufacturing Pall Corporation

Autojet Precision Lubrication System For Stamping Youtube

Spray Lubrication Systems Manufacturer Mumbai India Metal Working Machines System Spray

Autojet Precision Lubrication System For Pressing Forming Stamping Youtube

Fenn Torin Drawbenches Wire Drawing Bench Metal Bending Machine